Smart IoT Gateway – SIG4GTY-WP

The SIG4GTY-WP is an advanced IoT device designed for seamless deployment and monitoring in industrial settings. With support for up to 48 nodes, this versatile device employs RS-485 MODBUS protocol to read data from various industrial sensors.

The device also boasts communication failure detection, 4 DPDT relays for control actions, and a 128 x 64 graphical LCD display for clear status visualization.

The collected data is then transmitted to a cloud server using the MQTT protocol, allowing for efficient online monitoring. Key features include dual 4G SIM slots for redundancy, ensuring uninterrupted connectivity, and two settable alarm set-points for each channel with audio alarm indication through an inbuilt buzzer.

LPG / PNG / CNG GAS LEAK DETECTOR

Key Features

- Self test facility, Build in temperature sensor.

- PESO Certified Enclosure, Hooter Cum Flasher & Cable gland provides a fast & reliable response by using Catalytic / Pellistor / Semiconductor technology for detecting leak of LPG / PNG / CNG / LNG / Natural Gas / Flammable Gas.

- Highly resistant sensor to poisoning & etching.

- 2 numbers Alarm Relay Contacts configurable for warm, Alarm & Fault.

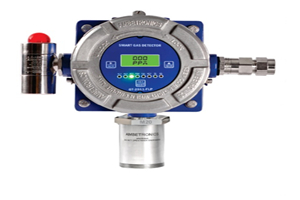

GAS DETECTION SYSTEM FOR AMMONIA REFRIGERATION PLANTS

Key Features

- Pluggable gas sensor module for Electro Chemical sensor

- IP-66 protection class

- Standard 4-20mA signal output

- Optional RS-485 Communication port with MODBUS RTU PROTOCOL.

- Supply voltage 18 to 36 VDC ( Typically 24 VDC)

- Send Text & E-mail Alerts ( Optional )

- Optional STEL & TWA set point.

H2S GAS DETECTION SYSTEM IN ETP PLANT

Key Features

- Provides a fast reliable output for detection a smallest leak of Toxic.

- Pluggable gas sensor module for Toxic sensor.

- Highly resistant to Poisoning and Etching.

- Capable of detecting down to PPM.

- Standard 4-20mA signal output with configurable range.

- Optional STEL and TWA set points can be configured for Toxic Gases.

- Optional RS-485 Communication port with MODBUS RTU PROTOCOL.